Nucor evaluates carbon-free reactor concept for mill power

Sources: Nucor Corp., Charlotte, N.C.; CP staff

A recently penned memorandum of understanding raises prospects for co-locating NuScale Power Corp. VOYGR small modular nuclear reactor (SMR) power plants to serve Nucor Corp. Electric Arc Furnace (EAF) steel mills. The companies will evaluate site suitability, transmission interconnection capabilities and capital costs for potential VOYGR installations, along with an expanded partnership delivering net-zero Nucor Econiq steel products for NuScale projects.

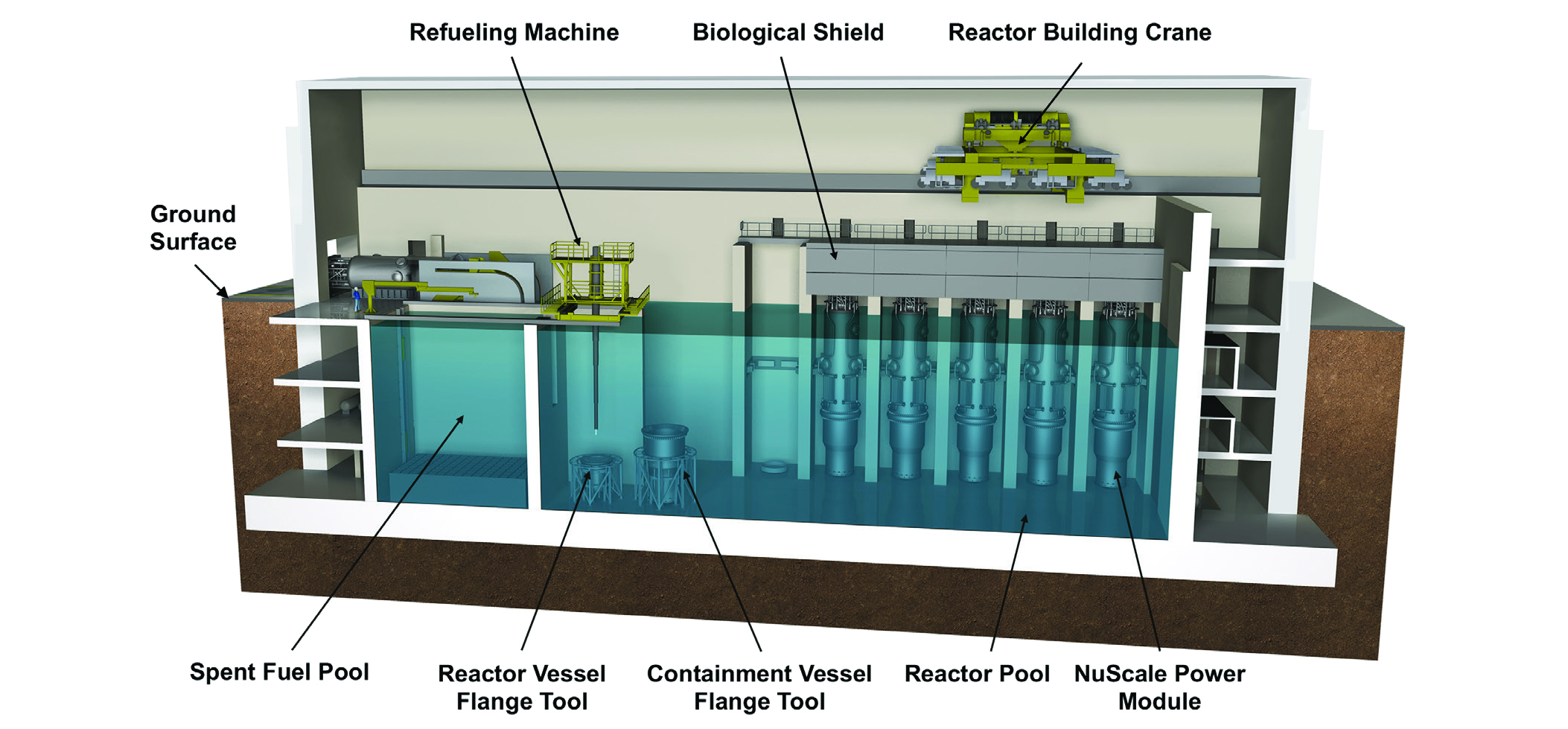

Configured with up to 12 NuScale Power Modules netting 924 MW of electricity (MWe), VOYGR power plants represent highly reliable, carbon-free energy sources for industrial applications. A pressurized water reactor, each Power Module can generate 77 MWe or 250 megawatts thermal (gross). As the sole U.S. Nuclear Regulatory Commission-approved and -certified SMR design, the VOYGR plant bears fully passive safety features which eliminate the need for an external grid connection to perform key safety functions and can achieve a site boundary Emergency Planning Zone, improving plant siting flexibility for industrial users like Nucor.

NUSCALE SMR, VOYGR POWER PLANT

The NuScale Power concept yields carbon-free electricity on a small fraction of the footprint typifying wind or solar farms.

“We look forward to determining how our SMR technology can best serve Nucor’s sophisticated steelmaking operations and how our companies can work together to drive a more sustainable future,” says NuScale Power CEO John Hopkins. “Nucor shares our commitment to sustainability and understands the role of our technology in delivering clean, reliable baseload power to support the global energy transition.”

“Nucor is committed to supporting the development of transformative technologies that will deploy safe, reliable, affordable, 24/7, base-load carbon free power,” adds Nucor Chair Leon Topalian. “Not only will Nucor’s partnership with NuScale help pave the way for a zero-carbon energy future, but we will be building this new generation with the cleanest steel products made anywhere in the world.”