Partnership eyes cement plant CO2 to synfuel conversion

Sources: Lafarge Canada Inc., Calgary; CMCM staff

Lafarge Canada, Svante Technologies Inc. and Dimensional Energy Inc. are poised to advance Project CO2MENT to its final phase: Utilization of 1 tonne of high-purity carbon dioxide from Lafarge Richmond (B.C.) cement plant flue exhaust—treated with Metal Organic Framework (MOF) advanced sorbent—to produce 1.5 barrels of synthetic hydrocarbon fuels. A specialist in processing synfuels from industrial CO2 streams, Dimensional Energy is joining a three-phase CO2MENT demonstration that Lafarge Canada, MOF carbon capture method developer Svante and French energy giant Total S.A. kicked off in 2019.

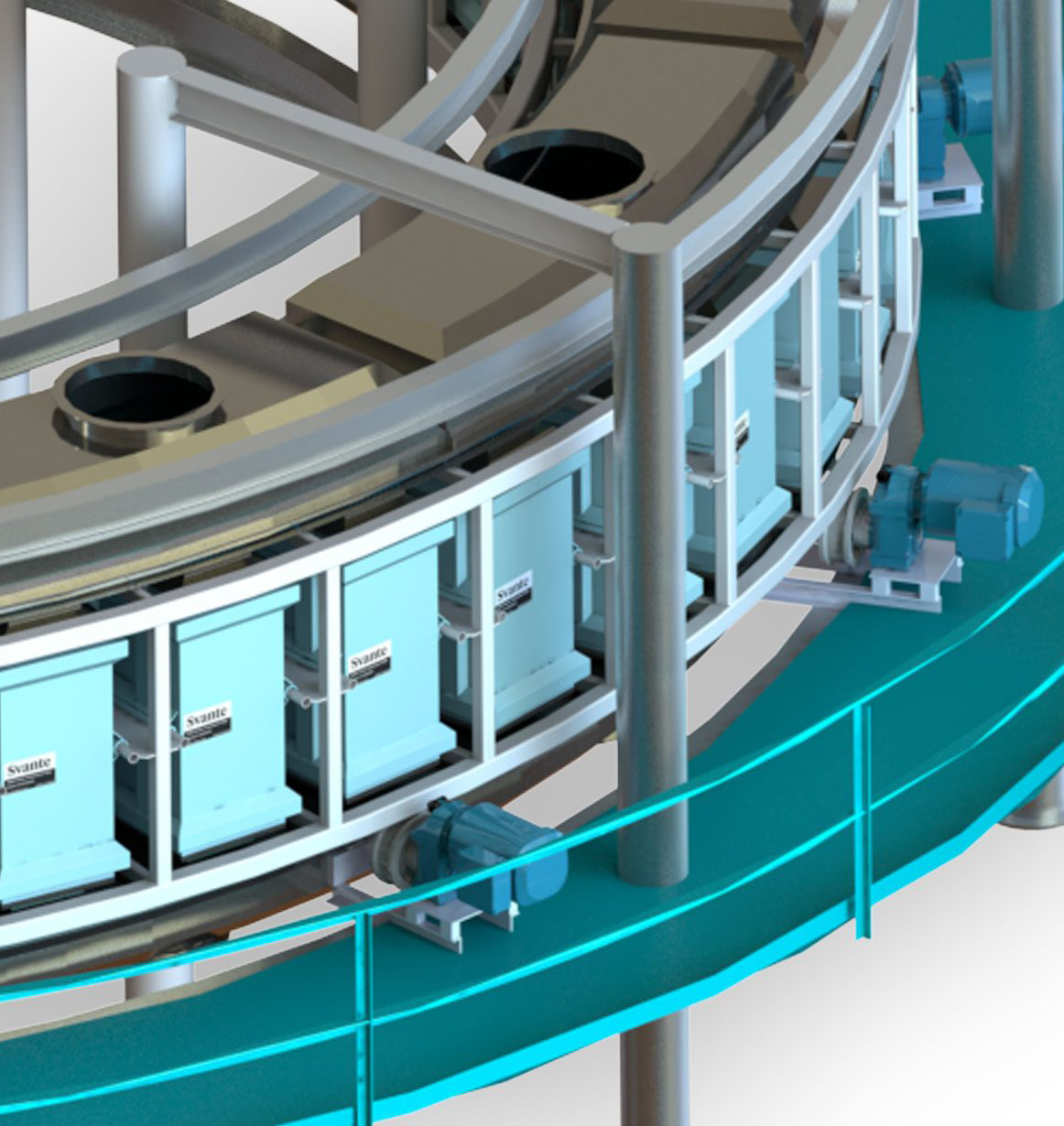

Burnaby, B.C.-based Svante Technologies tackles the pivotal question of carbon dioxide utilization or pipeline transfer, gas purity, by applying the emerging MOF process. The Svante concept envisions pressurizing and packaging CO2 for transfer from point source to end user.

The demonstration has allowed Svante to prove its technology in a cement production environment, focusing the last two years on pre-treatment of Richmond kiln flue gas and increasing the MOF advanced sorbent-based CO2 capture.

CO2MENT Phase 3 will see Dimensional Energy deploy its reactor and catalyst technology to covert the CO2 with green hydrogen to syngas. The output will be further processed into liquid hydrocarbons with Dimensional’s proprietary integration of downstream hydrocarbon synthesis. The synthetic hydrocarbons can be used in the production of industrial wax products and other high value products that place previously emitted carbon in an industrial use cycle. Premium grade pure waxes produced from Dimensional’s process will be of interest to other offtake partners such as manufacturers of plastics, lubricants and cosmetics.

“Carbon capture is an important lever in our net-zero roadmap. However, for a carbon capture project to succeed, it must be paired with permanent geologic sequestration or utilization technology that will permanently isolate the CO2in a specific media or product. If this pilot can be scaled to capture and use all facility emissions, it would be a first of its kind project for Lafarge and advance export and global adoption of this technology,” says Lafarge Western Canada Head of Sustainability & Environment Stephanie Voysey. Throughout the project, she adds, Lafarge has directed efforts to determine a suitable end use for the captured CO2, setting the stage for a third party, ISO verified life cycle analysis to advance the three partners’ overarching goal: Greenhouse gas emissions reduction.

Lafarge Canada Richmond plant

“Finding pathways to the viable use of the CO2 we capture from industrial sites is key in developing a circular carbon economy,” observes Svante CEO Claude Letourneau. “We must do everything we can to capture and remove CO2 before it reaches the atmosphere. This type of partnership and project could make a significant impact on the world if deployed at scale.”

“Together, we will transform carbon emissions to one of our greatest assets to grow a circular economy in better harmony with nature,” affirms Dimensional Energy CEO Jason Salfi. “Leveraging existing infrastructure in difficult to decarbonize sectors of our economy is where we, as technology providers, can have an immediate impact on abating carbon dioxide while providing growth and opportunity for all future generations.”